How to Make Your Own Cheesehead in Milwaukee

You can make your own iconic Cheesehead hat for this year’s football season at the Foamation factory in Milwaukee

To anyone who’s ever seen a Green Bay Packers game, the headwear of choice for many such fans should be immediately recognizable: a huge foam wedge of cheese. And though the hats aren’t made in Green Bay (in fact, the company that makes them, Foamation, isn't affiliated with the Packers at all), they are made in Wisconsin. Now, with a set of recently launched factory tours, you can visit cheese headquarters in Milwaukee and make your own.

For five dollars, you can book The Swiss tour, where you can sit in a back room and listen as a tour guide explains the history of the Cheesehead hat. The Cheddar tour, at $12, is the next level up, in which you'll get the history as well as a behind-the-scenes tour through the production area. But the big cheese of the tours is The Holey Cow, for $25. You get all the perks of the other tours, plus a make-and-take service that lets you create your own Cheesehead hat in the production room and take it home to keep.

The Cheesehead factory building is more than 100 years old, having started out as a foundry. The original safe from the first company to own the building is a point of pride for Foamation—though it doesn’t hold any money today. Rather, it contains the original Cheesehead hat.

According to tour guide Casey Gott—who dons the “commander in cheese” hat for the duration of each tour—Ralph Bruno, the CEO who still works at the company every day, invented the first Cheesehead in 1987. Chicago White Sox fans had taken to calling Milwaukee Brewers fans “Cheeseheads” as an insult. Bruno wasn’t quite sure what anyone had against cheese, so he decided to make the hat as a way to show that Wisconsinites embrace their cheesiness. At the time, he was reupholstering his mother’s couch, so he took one of the cushions and cut a wedge out of it. He used a blowtorch to put holes in it like Swiss cheese, and spray-painted the entire thing yellow. He wore it tailgating to a game, and by 1989, the hats had reached the mass market. Now, the company produces an array of foam hat creations, from corncobs and ice cream cones to hot wings and the Chicago Bears’ response to the Cheesehead, the graterhead—which looks like a giant cheese grater.

Each tour begins by taking the Wedge of Allegiance, a cheesy pledge to confirm you’ll stay safe in the factory, then visitors get a brief overview of the company’s history and a chance to see the original Cheesehead. Then, depending on the tour, you continue into the mold room. Foamation keeps every mold it’s ever used to make a hat, and the walls are lined with shelves of them. The flagship wedge is designed after three types of cheese: cheddar (because it’s yellow), Swiss (because it has holes), and Gouda (because it’s wheel-shaped). “No cheesemaker can make this type of cheese,” Gott said.

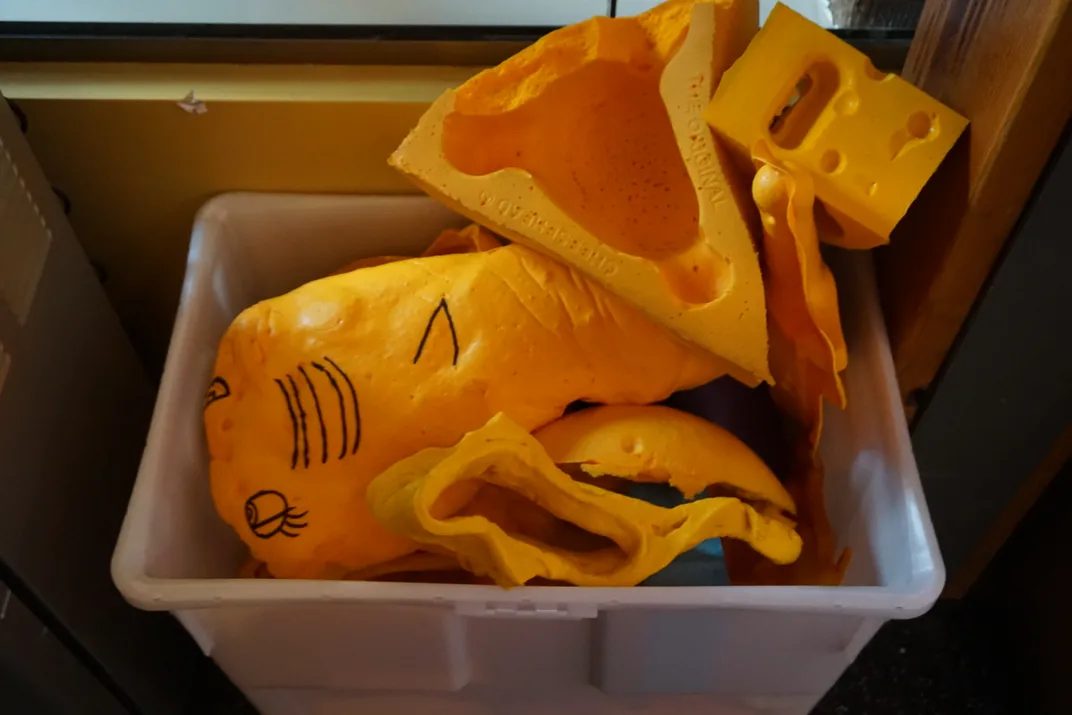

The Cheddar and The Holey Cow tours proceed into the small production room, where five partitioned stations make all the Cheeseheads seen across the world. The process to create the hats is deceptively simple. You take what looks like a large soda to-go cup and place it beneath an assembly of small tubes. A pre-measured amount of bright orange (or whatever the color of the item you’re making) polymeric isocyanate pumps into the cup from one tube, followed by another pre-measured amount of toluene diisocyanate from another tube. The two are then mixed together with a tool similar to a diner’s milkshake blender to create the polyurethane foam that forms the hats. The non-toxic liquid foam is then poured into a mold, which is clamped closed immediately after. Four minutes later, the foam has expanded and is set, the mold is opened, and you pull out your very own Cheesehead hat. Scrunch it all up once or twice to get any leftover air bubbles out, then don your new hat with pride. If there are any dangling edges, you can cut them off in the trimming room next to the production room. All the scraps—including the trimmings and botched products—are melted down and turned into carpet padding.

“My first day, when I walked in I was blown away by the building and that the cheesehats are made right here in Milwaukee,” Sean Patterson, a production employee at Foamation, told Smithsonian.com. “It brought a name to Wisconsin and it’s recognizable worldwide. The fact that it’s still handmade and family owned is great. To have tours on top of that is awesome. We don’t have anything to hide. We can open it up to anyone to have a fun experience in Milwaukee.”

Paul Schultz, a recent guest on the Holey Cow tour agreed—he won tickets in an auction and brought his son as a gift for his high school graduation. He was drawn by the fact that the company is still a family business and that the product is emblematic of Wisconsin, he told Smithsonian.com.

With the Holey Cow tour, you have the option to make more than just the standard cheese wedge hat. You can also make a baseball cap, cowboy hat, fedora, fireman hat, sombrero, top hat, a cheese dagger, a football, cheese wedge coasters, or Wisconsin-shaped coasters.

Or, if you're from Minnesota, perhaps this guide is more to your liking.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/JenniferBillock.png)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/JenniferBillock.png)